Amex® Seals

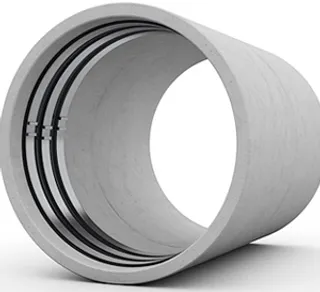

Amex® Seals are internal pipe repair sleeves that have been used to repair pipelines of different sizes, shapes, and mediums for over 40 years.

Amex-10 Mono

Amex-10 Vario

Amex-10 LEM

The surface is cleaned and smoothed. Then the PE backing band is placed over the join/damage.

The rubber part of the Amex® seal is placed, making sue the backing band is between the sealing lips.

The steel band is then placed in the grooves in the Amex® seal.

The hydraulic tool is then placed in the gap between the ends of the steel bands.

The hydraulic tool is pumped to 100 bar to provide initial pressure after which the supporting rod is secured to the top of the tool.

After achieving the proper pressure, a matching wedge is chosen and fitted in the gap created by the hydraulic tool, completing the installation.

Applications

Discover how we can support you, whatever your rehabilitation requirements.

Our Applications

Solutions

With our range of specialist trenchless solutions, you can ensure the health and efficiency of your pipelines, now and into the future.

Our Products