Sanitube

Our high performance stand-alone ‘pull in’ liner for trenchless rehabilitation of pressurised water, gas, petrol, oil and heating mains.

SaniTube® is ideally suited for the trenchless rehabilitation of all common types of pipes – water, gas, petrol, oil and heating mains – including cast-iron, ductile iron, steel, PVC and asbestos-cement pipes from DN25 to DN400. Available with polyethylene (PE) and polyurethane (PU) coatings.

Benefits

The pipe must be thoroughly cleaned, using pigs and scrapers if needed. The pipe must also be completely dry before installation begins.

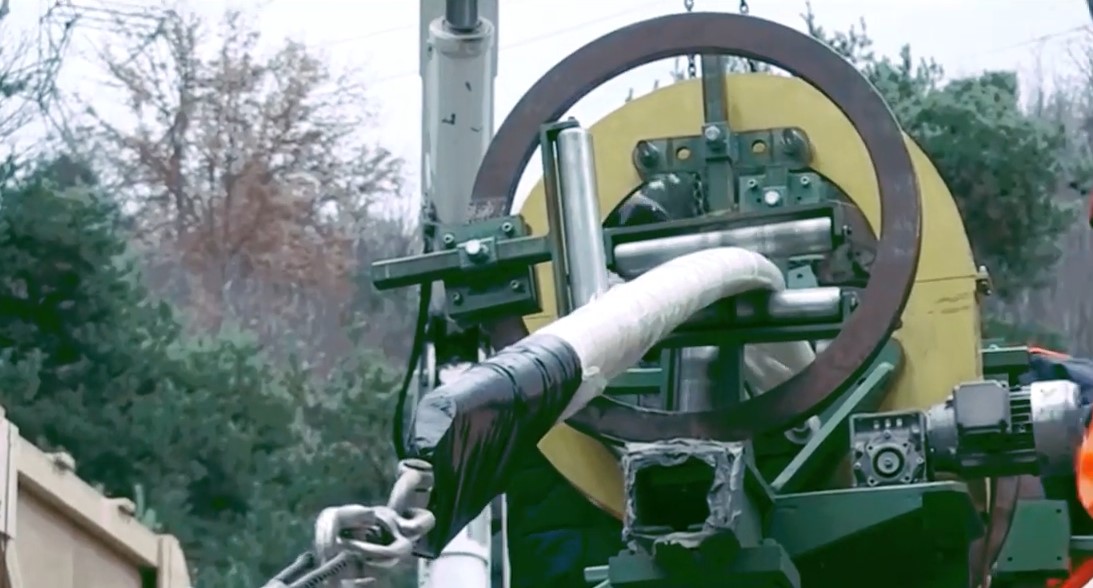

The winch is pulled from the exit pit to the entry pit and secured to SaniTube®, which is then pulled through the folding machine.

After this the liner is pulled through the pipe at a rate of 5-15 meters/minutes.

Once the liner is pulled through, a bladder is inserted and pressure is used to inflat the liner up to approximately 1 bar, breaking the tape.

The liner is now ready for SaniGrip© to be attached, thus securing the liner in place and preparing the host pipe to be reconnected and reinstated.

After all quality checks and tests are completed, the host pipe can be reinstated.

Applications

Discover how we can support you, whatever your rehabilitation requirements.

Our Applications

Products

With our range of specialist trenchless solutions, you can ensure the health and efficiency of your pipelines, now and into the future.

Our Products